(SVE/SPARGE-67) TRAILER, SVE/AIRSPARGE (AES# 40F) (SVE max 11″hg, 1450 scfm )(AS – max. 200 scfm, 13-31 psig) ***$ 43,000.00 ***

Trailer 40F 480V 3ph 26 SVE- 53 sparge points

Trailer – Homesteader 32 X 8 X 8 triple 5,000lb axles 6 lug 2 5/16” ball

Disconnect – 600V 250A 3ph breaker internally mounted in motor control enclosure with dead front controls front mounted

Control – Separate control panel with dead front. Relay logic

Control transformer – Hammond Power Solutions 5KVA front mounted

SVE 2-separate systems 28 points total

SVE Blowers – (2) National turbine Corp. model NT55203-3-0-60 25hp 480V 3ph 28fla each

(2) 2” 14 point with ERDCO model 711-10T100S flow meters and gate valves into (2) 6” aluminum manifolds with 6” bypass gate valves to 2 6” inlets

Exhaust – 6” on each pump with flow meters and temperature gauges and sample port into 1-6” out

Dwyer 1950 differential pressure switches and mercoid temperature switches on each manifold

A/W separator Tank – Bisco 200 gallon with 6” inlet from manifolds

With level switch array and site glass

Transfer Pump – Gould NPE 1 ST1D6B4 2hp 480V3ph 2.1fla

GPM meter – Badger Meter with only 5,120 gallons registered

Bag Filter – Micron Technologies modelH5040P300A

Carbon Vessel – 90lb fiber glass to 1” out

Sparge 3 separate systems 53 points total

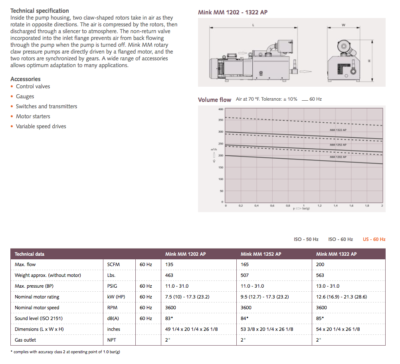

Sparge Pumps – (3) Busch Mink 1322AP 18.5KW (15hp) 3ph 480V 16.0FLA each

Heat Exchangers – (3) American Industrial model ACA6302-3 1hp 3ph 480V 1.1fla

Temperature switches – Barksdale model ML-1H-H203 and output temperature gauges and gate valves

Manifolds – (3) 2” 1-19 point, 2-17 point with gate valves and pressure gauges

Flow Rate Meters – (53) Chemline model 13750-46303

Differential Pressure Switches – (3)Dwyer 1950P

All sparge points 1” out

*Manual with equipment specs and electrical drawings*